Specification:

The difference between its anisotropy and isotropy lies in whether there is an orientation magnetic field during press molding. The wet pressing process includes:

Raw materials---Pre-burning---Coarse grinding (primary ball milling)--- Ingredients---Secondary ball milling (wet grinding)---Magnetic field forming---Sintering---Grinding- --Cleaning---Magnetizing.

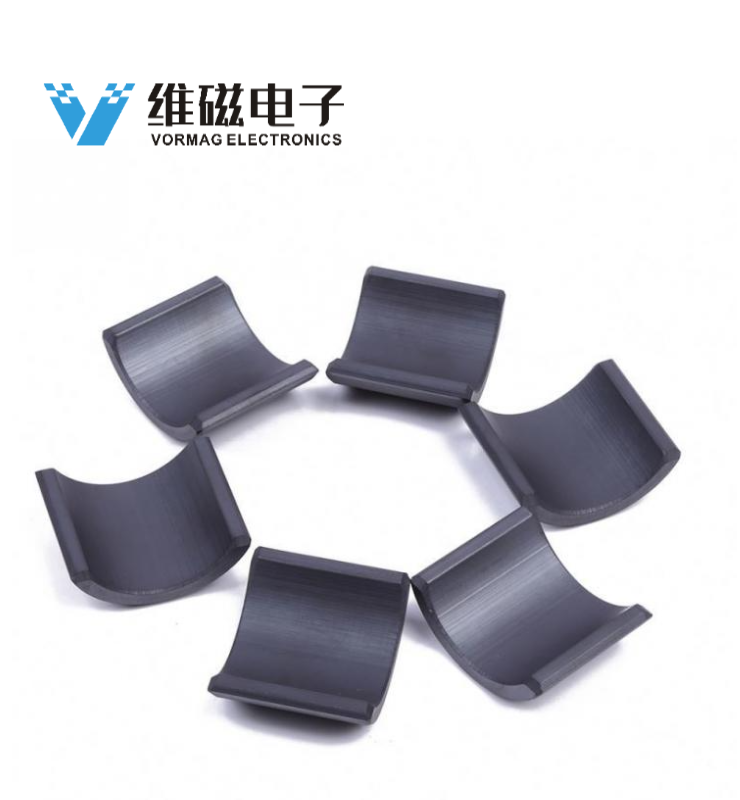

Because the molding slurry contains water, the particles formed in the magnetic field are easy to turn, so they can obtain a higher degree of orientation than the dry pressure, and the performance will be higher. Wet-pressed ferrite magnet tiles / segment are the most important category of permanent ferrite products.

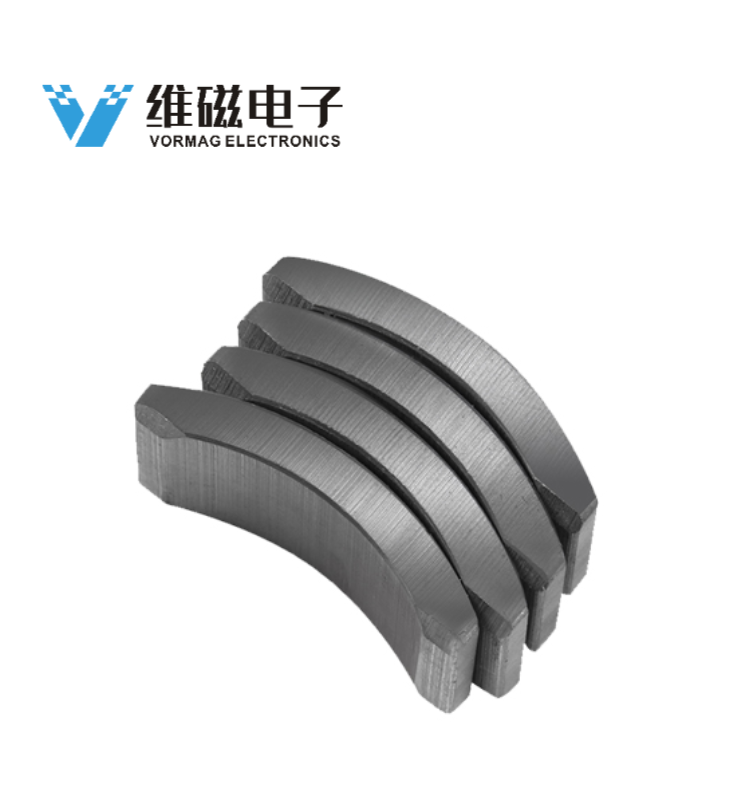

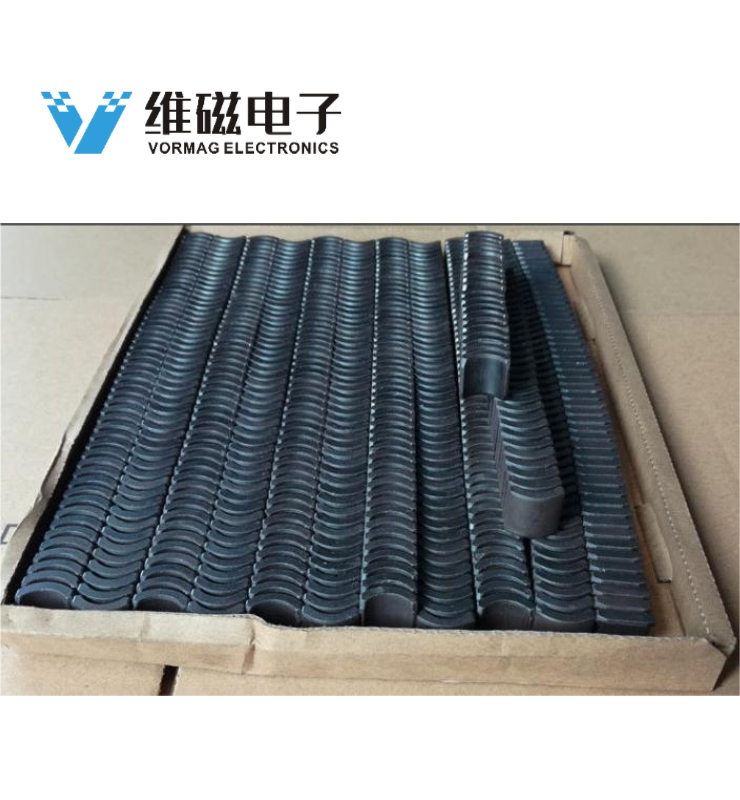

Segments for Fan Motors.png)