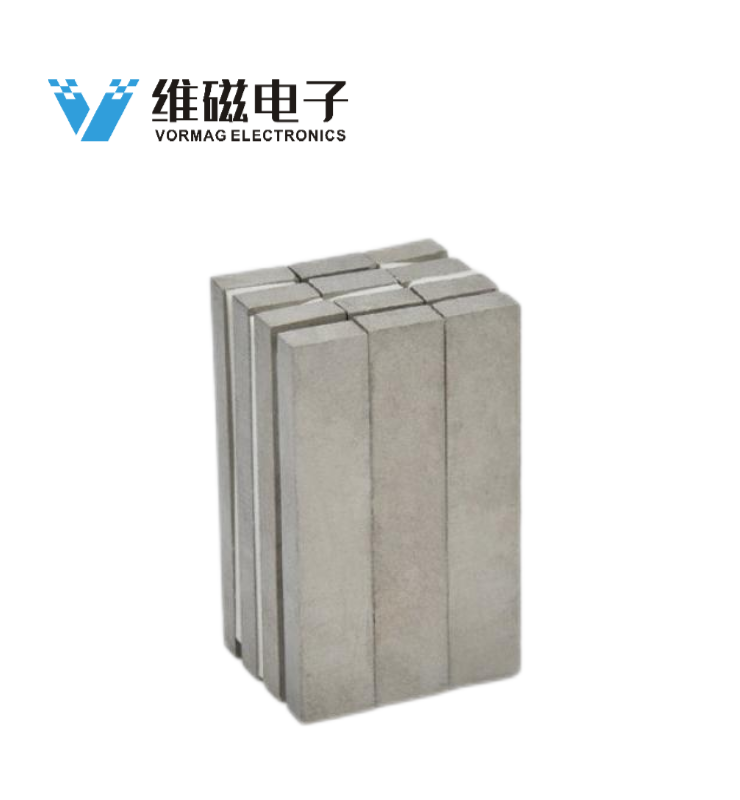

Samarium Cobalt (SmCo) Magnets is also known as SmCo, Rare Earth Cobalt, RE Cobalt, RECo and CoSm. Samarium Cobalt (SmCo) magnets containing two basic elements samarium and cobalt is part of the rare-earth magnet family of permanent magnets along with neodymium magnets, are made by a sintering process and exist in two forms.

According to crystal structure, samarium cobalt magnets include SmCo5 magnets (1st generation of REPMs) and Sm2Co17 magnets (2nd generation of REPMs). Sm1Co5 (SmCo1:5) is the original SmCo alloy and this has a maximum energy product of between 14 and 24 MGOe. Sm2Co17 (SmCo2:17) is the more common used and stronger SmCo alloy with SmCo26 being the most popular variety.

Corrosion Resistance

SmCo magnets can usually be used in humid applications without any need for a protective coating. In wet envrironments, coating of SmCo(2:17) in NiCuNi is recommended to avoid surface corrosion issue.

The corrosion resistant of SmCo magnets are considered good, surface coating is unnecessary, but the coatings like NiCuNi, Zn, Black epoxy can be plated if required. The oxidation resistance behavior of SmCo (2:17)-type high-temperature magnets modified with Ni–Cr two-layer coating is under studied.

Excellent Temperature Stability

Samarium cobalt magnets experience a minimal change in their magnetic performance as temperature increases from ambient, far less than neodymium and ferrite (ceramic) magnets. Being part of the rare-earth magnet family, Samarium cobalt magnets rank similarly in strength to neodymium magnets but have much higher temperature stability and higher coercivity.

| Physical properties of sintered Sm-Co magnets | |

| Property (unit) | Sm-Co |

| Remanence (T) | 0.8–1.16 |

| Coercivity (MA/m) | 0.493–2.79 |

| Relative permeability (–) | 1.05–1.1 |

| Temperature coefficient of remanence (%/K) | −0.03..–0.05 |

| Temperature coefficient of coercivity (%/K) | −0.15..–0.30 |

| Curie temperature (°C) | 700–850 |

| Density (g/cm3) | 8.2–8.5 |

| CTE, magnetizing direction (1/K) | (5–9)×10−6 |

| CTE, normal to magnetizing direction (1/K) | (10–13)×10−6 |

| Flexural strength (N/mm2) | 150–180 |

| Compressive strength (N/mm2) | 800–1000 |

| Tensile strength (N/mm2) | 35–40 |

| Vickers hardness (HV) | 400–650 |

| Electrical resistivity (Ω·cm) | (50–90)×10−6 |