Technical specification:

Shape: Disc round

Dimensions: D25 x 10mm (diameter x thickness)

Default tolerance: +/-0.1mm Or customize as required

Plating/coating: Black epoxy coated

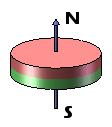

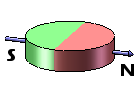

Magnetism direction: Axial Or Customized

Material: NdFeB (sintered neodymium-iron-boron)

Grade: N52

Epoxy enables better grip for magnet separation and prevents scratches to other objects.

The epoxy coating provides a barrier between magnets and deteriorating substances. This allows our Waterproof Neodymium Disc Magnets to be used for a longer time in a certain environment.

| Characteristic | Symbol | Unit | Value |

| Density | D | g/cm | 7.45-7.65 |

| Vickers Hardness | Hv | D.P.N | 620 |

| Compression Strength | C.S | N/mm2 | 780 |

| Coefcient of Thermal Expansion | C// | 10-6/°C | 3.4 |

| CŁ | 10-6/°C | -4.8 | |

| Electrical Resistivity | ƿ | µ Ω.cm | 1.8x10 x^(-4) |

| Temperature coefcient of resistivity | α | 10x^(-4)/°C | 2 |

| Electrical Conductivity | σ | kCal/(m.h.°C) | 0.667 |

| Thermal Conductivity | k | kCal/(kg.°C) | 8.9551 |

| Specifc Heat Capacity | c | kg/mm2 | 0.12 |

| Tensile Strength | σUTS, or SU | Mpa | 80 |

| Young's Modulus | λ / E | 10-12m2/N | 0.16x1011 |

| Flexural Strength | β | 10-12m2/N | 9.8 |

| Compressibility | σ | 10-12m2/N | 9.8 |

| Rigidity | E.I | N/m2 | 0.64 |

| Poisson's Ratio | ν | 0.24 | |

| Curie Temperature | Tc | °C | 310-380 |

NdFeB magnets are sintered anisotropic materials - they have a preferred direction of magnetisation locked into their structure.

Neodymium magnets come in many shapes and sizes, and different shapes have corresponding magnetization directions.

Disk, cylindrical and ring magnets can be magnetized Axially or Radially. Axially magnetized disc magnets have north and south pole s on a large flat surface. Radially magnetized disc magnets have north and south poles on the sides of the circle.

In order to let the customer distinguish the N-S pole easily, we can offer North / South Pole marked, this is a simply marking on the North / South pole of the magnet - does not affect tolerance. The marking of polarity is not the default service, we will not apply this to our production unless the customers make their own requests.